Automated Cookie Factory Line

Fall 2022

Project Goals

The goal of this project was to fully automate a factory line simulating a cookie factory.

This was an academic project associated with a class about Industrial Motor Control and Programmable Logic Controllers (PLCs). PLCs are simply the standardized type of computers used to automate industrial processes. PLCs use a special visual programming language called Ladder Logic to communicate instructions. In this instance, we were using Allen-Bradley PLCs with Rockwell Automation software.

Because of the nature of the cost of the PLCs and Ladder Logic software, the students were restricted to working on the project in the lab. To maintain rigor of the course, each student had to complete their own project in the course of finals week (seven days). An additional factor to be considered is that the PLCs and programming software were too expensive for the University to have more than 4 models working at the beginning of the week, 7 by the end (on borrowed parts). That was in a class of ~35.

Despite this project being simulated and academic in nature, there was literally no difference between how one would program the simulated version and the real deal. One could very well load the program directly onto a real sized model and it would work just fine without modification. The simulation included real, working, scaled-down versions of all mechanical parts, so as to keep the students honest with themselves.

Evaluation

The assignment sheet continued:

“The operation of this sorting system will be divided into four operational states; Startup, Normal Operation, Shutdown, & Reverse Operation.

Your completed program will be evaluated on whether or not it provides the proper operational logic for each of the operational states with the following weighting:

Startup - 25% Normal Operation - 50%

Shutdown - 15% Reverse Operation - 10%

***Note that you may only move onto a section after the previous section has been completed. They must be completed in order.”

Assignment

The assignment sheet started as follows:

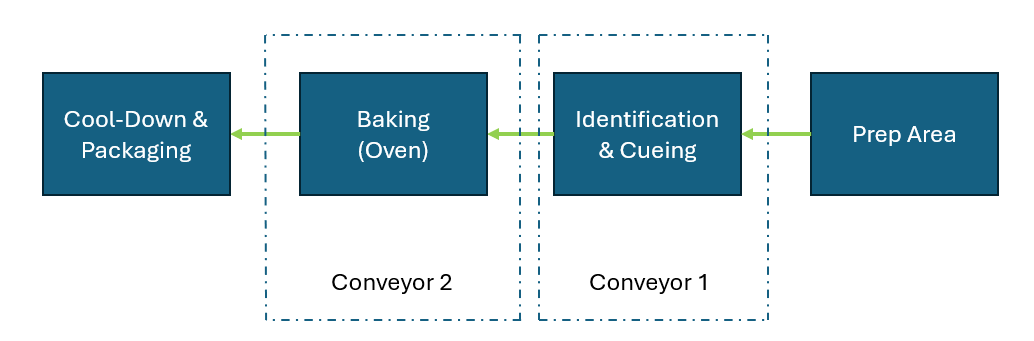

“You are tasked with creating a ladder-logic based program that, when downloaded into a PLC and the PLC is switched to RUN mode, will provide the operational logic for a simple conveyor-driven, production line oven that will be used in a local confectionary.”

Results

All of the possible goals of this project as laid out in the syllabus were met accurately and precisely. Consequently, I earned an A+ on this project (the final exam for the course) and subsequently passed the class as well.

In total, I spent approximately 80 hours in the lab working on this project in that last finals week of my academic career. I also worked my usual 40 hours at work that week. That was the hardest I have ever worked in a week, but was certainly worth it. I consider myself pretty lucky on that front because the students who didn’t have programming experience took about 120 hours in the lab that week to pass the assignment.